Gas turbines

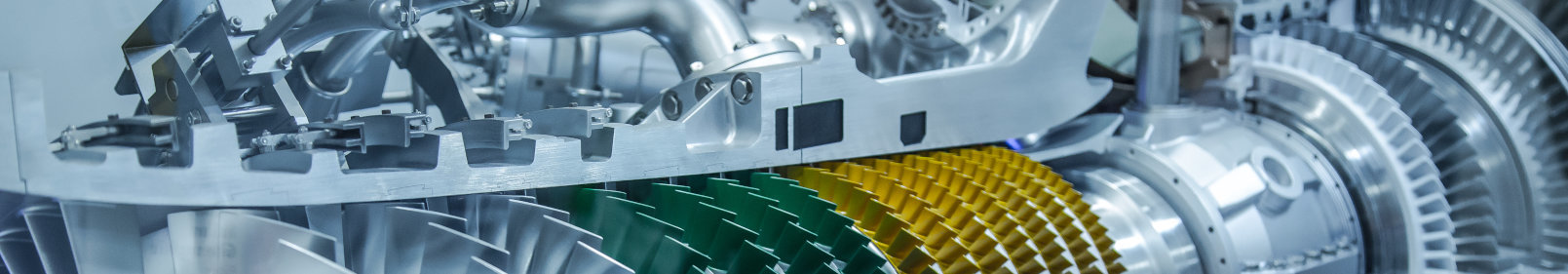

Modern gas power plants offer a cost-effective alternative to electricity generation from domestic lignite-fired power plants in equivalent performance classes. The advantage is the significantly reduced CO2 emissions and the outstanding efficiency in operation in the "Combined Cycle". The "Combined Cycle" is characterized by an additional installation of a steam process with several steam turbines, which uses the residual gas heat of the gas turbine to generate steam and converts it into shaft power.

Performance, availability, operational safety, efficiency and environmental compatibility depend essentially on how the components (compressor, combustion chamber, turbine) are designed. On the one hand, the quality of the individual components is important. In addition, the individual components and their interfaces must be optimally coordinated with one another. Expertise and development work are required here.

AYED-ENGINEERING supports manufacturers in the development of new turbines. In addition, our experts contribute their many years of experience, their comprehensive know-how and their "toolbox" with helpful tools for upgrade concepts. We create potential analyzes and feasibility studies and develop concepts to increase performance and efficiency. This is how we develop previously unused optimization potential for our customers.

Besides the design and optimization of components, we also support damage analysis. In addition to root cause analysis, this also includes the development of concepts for root cause resolution.

The material used in gas turbines requires particular attention. This is exposed to the highest loads. Incorrect material selection and material defects often result in expensive damage and downtime. AYED-ENGINEERING has extensive expertise in the design of gas turbine components. We develop cooling concepts, provide support in the construction of spare parts, advise on repairs and create failure analyses.

![[Translate to Englisch:] Scroll Up [Translate to Englisch:] Scroll Up](/fileadmin/_processed_/b/1/csm_arrow-up_5be49f2193.jpg)